Product Series Parameters of Mainstream Yunnan Telescopic Casing Manufacturers

I. Introduction

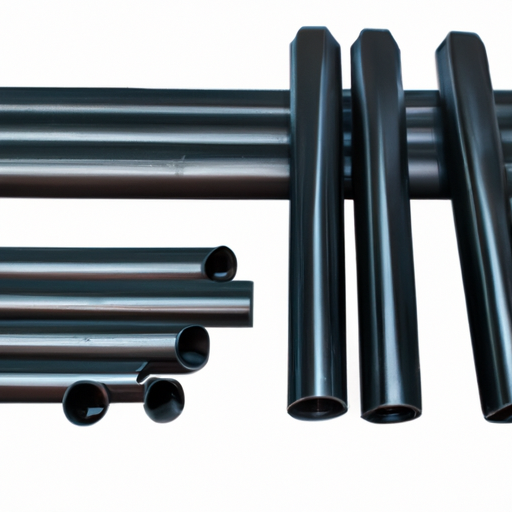

A. Overview of Telescopic Casings

Telescopic casings are essential components in various industries, designed to provide adjustable support and protection for equipment and structures. These casings are characterized by their ability to extend and retract, allowing for flexibility in height and size. Their primary purpose is to accommodate different operational needs while ensuring stability and safety.

B. Significance of Yunnan in the Telescopic Casing Market

Yunnan, a province in southwestern China, has emerged as a significant player in the telescopic casing market. Its geographic advantages, including access to abundant natural resources and a strategic location for trade, have fostered a robust manufacturing sector. The economic impact of local manufacturing is profound, contributing to job creation and technological advancements in the region.

II. Overview of Mainstream Manufacturers in Yunnan

A. Key Players in the Market

Yunnan is home to several mainstream manufacturers of telescopic casings, each contributing uniquely to the market landscape.

1. **Company A**: Known for its innovative designs and high-quality materials, Company A has established a strong reputation in the construction and telecommunications sectors.

2. **Company B**: This manufacturer focuses on sustainable practices and has integrated eco-friendly materials into its product lines, appealing to environmentally conscious consumers.

3. **Company C**: With a diverse range of products, Company C caters to various industries, including oil and gas, and is recognized for its competitive pricing and reliable performance.

B. Market Share and Positioning

The competitive landscape in Yunnan's telescopic casing market is dynamic. A comparative analysis reveals that while Company A leads in market share due to its advanced technology, Company B is rapidly gaining ground with its sustainable offerings. Each manufacturer has unique selling propositions (USPs) that differentiate them, such as Company A's focus on innovation and Company C's emphasis on affordability.

III. Product Series Parameters

A. Material Specifications

The materials used in telescopic casings significantly influence their performance and durability. Common materials include:

1. **Steel**: Known for its strength and durability, steel is widely used but can be heavy and prone to corrosion if not treated properly.

2. **Aluminum**: Lightweight and resistant to corrosion, aluminum is ideal for applications requiring mobility. However, it may not support as much weight as steel.

3. **Composites**: These materials offer a balance of strength and weight, often used in specialized applications. They can be more expensive but provide excellent performance.

B. Size and Dimensions

Manufacturers in Yunnan offer a range of standard sizes for telescopic casings, typically designed to meet common industry requirements. Customization options are also available, allowing clients to specify dimensions that suit their unique needs. This flexibility is crucial for industries like construction, where site conditions can vary significantly.

C. Load Capacity

Load capacity is a critical parameter for telescopic casings. Manufacturers provide detailed specifications regarding weight limits and performance metrics. Testing standards and certifications ensure that products meet safety and reliability benchmarks, which is essential for industries that rely on these components for structural integrity.

D. Design Features

The design of telescopic casings includes various mechanisms that facilitate extension and retraction. Safety features, such as locking mechanisms and compliance with industry regulations, are integral to their design. These features enhance user confidence and ensure that the casings perform reliably under different conditions.

E. Surface Treatments and Finishes

Surface treatments play a vital role in the longevity of telescopic casings. Common coatings include:

1. **Powder Coating**: Provides a durable finish that resists scratches and corrosion.

2. **Anodizing**: Often used for aluminum casings, anodizing enhances corrosion resistance and improves aesthetic appeal.

These treatments not only enhance durability but also reduce maintenance needs, making them attractive to end-users.

IV. Technological Innovations

A. Advancements in Manufacturing Processes

Yunnan manufacturers are increasingly adopting advanced manufacturing processes, including automation and precision engineering. These innovations lead to higher efficiency, reduced production costs, and improved product quality. Additionally, sustainable practices are being integrated into production, minimizing environmental impact.

B. Integration of Smart Technologies

The integration of smart technologies into telescopic casings is a growing trend. Internet of Things (IoT) applications allow for real-time monitoring of performance metrics, enhancing operational efficiency. Smart features can provide alerts for maintenance needs, ensuring that equipment remains in optimal condition.

V. Applications of Telescopic Casings

A. Industries Utilizing Telescopic Casings

Telescopic casings find applications across various industries:

1. **Construction**: Used for scaffolding and support structures, providing adjustable height and stability.

2. **Telecommunications**: Essential for antenna installations, allowing for height adjustments based on signal requirements.

3. **Oil and Gas**: Employed in drilling operations, where adaptability and strength are crucial.

B. Case Studies of Successful Implementations

1. **Construction Industry**: A major construction project in Yunnan utilized telescopic casings to support temporary structures, allowing for quick adjustments as the project progressed. This flexibility resulted in significant time and cost savings.

2. **Telecommunications**: A telecommunications company implemented telescopic casings for antenna installations, enabling precise height adjustments that improved signal quality and coverage.

VI. Challenges and Considerations

A. Market Challenges

Despite the growth potential, Yunnan's telescopic casing manufacturers face challenges, including competition from other regions and economic fluctuations that can affect demand. Staying competitive requires continuous innovation and adaptation to market trends.

B. Quality Control and Standards

Maintaining high-quality standards is paramount in the telescopic casing industry. Manufacturers must adhere to regulatory compliance and certifications to ensure product safety and reliability. Quality control processes are essential to meet the expectations of clients across various sectors.

VII. Future Trends in the Telescopic Casing Market

A. Predictions for Market Growth

The telescopic casing market is poised for growth, driven by emerging markets and increasing demand for adaptable solutions. Opportunities for innovation, particularly in smart technologies and sustainable materials, will shape the future landscape.

B. Role of Yunnan Manufacturers in the Global Market

Yunnan manufacturers are well-positioned to compete in the global market. By focusing on quality, innovation, and collaboration with international partners, they can enhance their competitiveness and expand their reach.

VIII. Conclusion

A. Summary of Key Points

The telescopic casing market in Yunnan is characterized by a diverse range of manufacturers, each offering unique products and solutions. Key parameters such as material specifications, size, load capacity, and design features play a crucial role in determining the suitability of these casings for various applications.

B. Final Thoughts on the Importance of Yunnan Manufacturers in the Telescopic Casing Industry

Yunnan's manufacturers are integral to the growth and development of the telescopic casing industry. Their commitment to quality, innovation, and sustainability positions them as leaders in the market.

C. Call to Action for Stakeholders in the Industry

Stakeholders in the telescopic casing industry should collaborate to drive innovation and address market challenges. By investing in research and development, embracing new technologies, and maintaining high standards, they can ensure the continued success of the industry.

IX. References

A comprehensive list of studies, articles, and industry reports will be provided to support the insights shared in this blog post, along with acknowledgments to manufacturers and experts who contributed to the understanding of the telescopic casing market in Yunnan.