Similar Recommendations for Cable Hole Telescopic Sleeve Components

I. Introduction

In the world of electrical and telecommunications installations, the importance of cable management cannot be overstated. Among the various components that facilitate effective cable management, cable hole telescopic sleeve components stand out for their versatility and functionality. These components are designed to protect and organize cables, ensuring that they remain secure and accessible. This article aims to provide insights into cable hole telescopic sleeves, explore similar components, and offer recommendations for selecting the right solutions for your specific needs.

II. Overview of Cable Hole Telescopic Sleeve Components

A. Description and Functionality

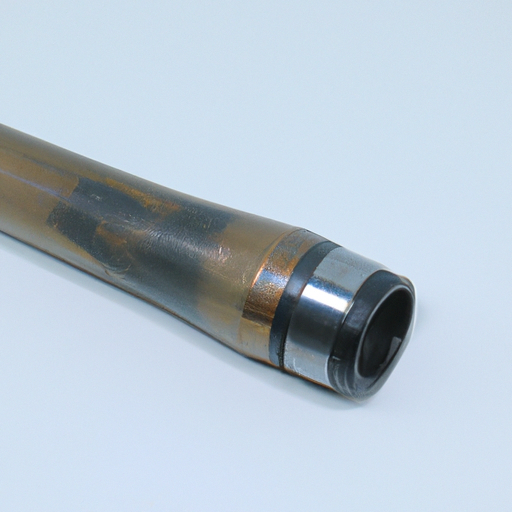

Cable hole telescopic sleeves are specialized components that allow for the passage of cables through walls, ceilings, or other barriers while providing protection and organization. Their design features typically include a telescopic mechanism that enables them to extend or retract, accommodating varying cable lengths and installation scenarios.

1. Design Features

The telescopic design allows for flexibility in installation, making it easier to manage cables of different lengths. These sleeves often come with a smooth inner surface to minimize friction and wear on the cables, as well as external ridges or grooves that enhance grip and stability.

2. Materials Used

Cable hole telescopic sleeves are commonly made from durable materials such as PVC, polyethylene, or rubber. These materials are chosen for their resistance to environmental factors, including moisture, UV radiation, and temperature fluctuations, ensuring that the sleeves maintain their integrity over time.

B. Common Applications

Cable hole telescopic sleeves find applications in various industries, including:

1. Telecommunications

In telecommunications, these sleeves are essential for protecting and organizing the multitude of cables that connect different devices and systems. They help maintain signal integrity and reduce the risk of damage from environmental factors.

2. Electrical Installations

In electrical installations, telescopic sleeves provide a safe passage for electrical wiring, ensuring that cables are protected from physical damage and environmental hazards. They are particularly useful in commercial and industrial settings where cable management is critical.

3. Automotive Industry

The automotive industry also benefits from cable hole telescopic sleeves, as they help manage wiring harnesses and other electrical components within vehicles. Their flexibility allows for easy routing of cables, which is essential for maintaining the functionality of various systems.

C. Benefits of Using Telescopic Sleeves

The use of cable hole telescopic sleeves offers several advantages:

1. Flexibility and Adaptability

The telescopic design allows for easy adjustments, making it simple to accommodate changes in cable lengths or installation requirements. This adaptability is particularly beneficial in dynamic environments where modifications may be necessary.

2. Protection Against Environmental Factors

These sleeves provide a protective barrier against moisture, dust, and other environmental elements that could potentially damage cables. This protection is crucial for maintaining the longevity and performance of the cables.

3. Ease of Installation

Cable hole telescopic sleeves are designed for straightforward installation, often requiring minimal tools and expertise. This ease of use can save time and labor costs during installation projects.

III. Similar Components and Alternatives

While cable hole telescopic sleeves are highly effective, there are several similar components and alternatives that can also be considered for cable management.

A. Overview of Similar Components

1. Cable Management Sleeves

Cable management sleeves are designed to bundle and organize multiple cables, providing a neat and tidy appearance. They are often made from flexible materials that allow for easy routing and adjustment.

2. Conduit Systems

Conduit systems offer a more rigid solution for cable protection. These systems are typically made from metal or plastic and provide a secure pathway for cables, protecting them from physical damage.

3. Heat Shrink Tubing

Heat shrink tubing is a versatile option for insulating and protecting individual cables. When heated, the tubing shrinks to fit snugly around the cable, providing a secure and protective covering.

B. Comparison of Features and Benefits

When comparing these components, several factors should be considered:

1. Material Differences

Cable management sleeves are often made from softer materials, while conduit systems are more rigid. The choice of material can impact the level of protection and flexibility offered by each component.

2. Installation Processes

Installation processes vary among these components. Telescopic sleeves and cable management sleeves are generally easier to install, while conduit systems may require more extensive labor and tools.

3. Cost Considerations

Cost is an important factor when selecting cable management solutions. Telescopic sleeves and cable management sleeves tend to be more affordable, while conduit systems may involve higher material and installation costs.

IV. Recommendations for Selecting the Right Component

Choosing the right cable management component requires careful consideration of several factors.

A. Factors to Consider

1. Application Requirements

Understanding the specific requirements of your application is crucial. Consider the type of cables being used, the environment in which they will be installed, and any regulatory standards that must be met.

2. Environmental Conditions

Evaluate the environmental conditions that the cables will be exposed to. Factors such as moisture, temperature fluctuations, and exposure to chemicals can influence the choice of materials and components.

3. Budget Constraints

Establishing a budget is essential for selecting the right components. Consider not only the initial costs but also the long-term value and durability of the components.

B. Tips for Evaluating Quality and Performance

1. Certifications and Standards

Look for components that meet industry certifications and standards. This ensures that the products have been tested for quality and performance.

2. Manufacturer Reputation

Research the reputation of manufacturers and suppliers. Established companies with a history of producing reliable products are often a safer choice.

3. Customer Reviews and Feedback

Reading customer reviews and feedback can provide valuable insights into the performance and reliability of specific components. Look for testimonials from users in similar applications.

V. Case Studies and Examples

A. Successful Implementations of Cable Hole Telescopic Sleeves

In a telecommunications project, a company implemented cable hole telescopic sleeves to manage the extensive cabling required for a new data center. The flexibility of the sleeves allowed for easy adjustments during installation, resulting in a streamlined process and reduced labor costs.

B. Scenarios Where Alternative Components Were Used Effectively

In an automotive manufacturing facility, conduit systems were used to protect wiring harnesses from potential damage during assembly. The rigid structure of the conduit provided the necessary protection in a high-traffic environment.

C. Lessons Learned from Various Applications

One key lesson learned from these implementations is the importance of selecting the right component for the specific application. While telescopic sleeves offer flexibility, there are scenarios where more rigid solutions may be necessary for optimal protection.

VI. Future Trends in Cable Management Solutions

A. Innovations in Materials and Design

The cable management industry is witnessing innovations in materials and design, with a focus on enhancing durability and flexibility. New materials that offer improved resistance to environmental factors are being developed.

B. The Impact of Technology on Cable Management

Advancements in technology are also influencing cable management solutions. Smart cable management systems that incorporate sensors and monitoring capabilities are emerging, allowing for real-time tracking and management of cables.

C. Predictions for the Future of Cable Hole Telescopic Sleeves and Similar Components

As the demand for efficient cable management continues to grow, it is likely that cable hole telescopic sleeves and similar components will evolve to meet the changing needs of various industries. Expect to see more customizable options and enhanced features that improve usability and performance.

VII. Conclusion

In conclusion, selecting the right cable management components is crucial for ensuring the safety and efficiency of electrical and telecommunications installations. Cable hole telescopic sleeves offer a versatile solution, but it is essential to explore various options and consider specific application requirements. By understanding the benefits and features of different components, you can make informed decisions that enhance the performance and longevity of your cable management systems.

VIII. References

- Industry standards and guidelines related to cable management components.

- Manufacturer specifications and product datasheets.

- Customer reviews and case studies from various applications.

By taking the time to evaluate your options and consider the insights provided in this article, you can navigate the evolving landscape of cable management solutions with confidence.