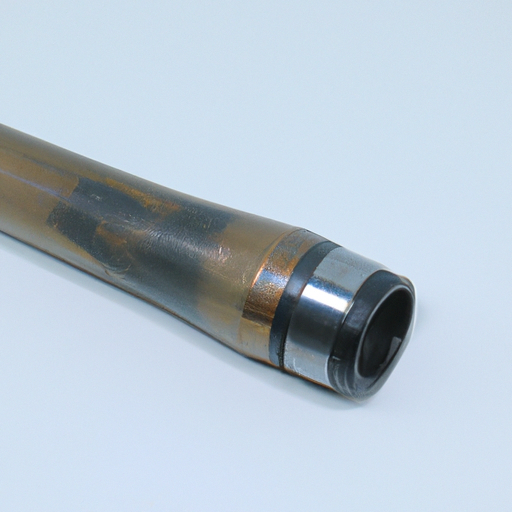

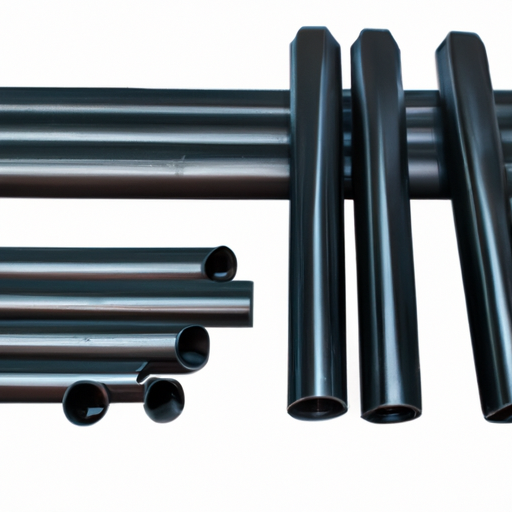

What is the Market Size of Telescopic Casing Quotations in Gansu? I. Introduction A. Definition of Telescopic CasingTelescopic casing refers to a type of casing used primarily in the oil and gas industry, as well as in construction and mining. It consists of a series of tubes that can be extended or retracted, allowing for flexibility in various applications. This adaptability makes telescopic casing an essential component in drilling operations, where it can accommodate changes in depth and geological conditions. B. Importance of Telescopic Casing in Various IndustriesThe significance of telescopic casing extends beyond its mechanical properties. In the oil and gas sector, it plays a crucial role in ensuring the safety and efficiency of drilling operations. In construction, it provides structural support and stability, while in mining, it aids in the extraction of resources. As industries continue to evolve, the demand for reliable and innovative casing solutions is expected to grow. C. Overview of Gansu Province and Its Economic ContextGansu Province, located in north-central China, is known for its diverse geography and rich natural resources. The province has been undergoing significant economic development, driven by investments in infrastructure and industrial growth. As Gansu continues to expand its industrial base, the demand for telescopic casing is likely to increase, making it a focal point for market analysis. II. Overview of the Telescopic Casing Market A. Global Market Trends 1. Growth DriversThe global telescopic casing market is experiencing robust growth, driven by several factors. The increasing demand for energy, particularly in emerging economies, is propelling investments in oil and gas exploration. Additionally, the construction sector's expansion, fueled by urbanization and infrastructure projects, is further driving the need for telescopic casing solutions. 2. Key PlayersKey players in the telescopic casing market include major manufacturers and suppliers who are continuously innovating to meet the evolving needs of various industries. Companies such as Schlumberger, Halliburton, and National Oilwell Varco are at the forefront, providing advanced casing solutions that enhance operational efficiency. B. Regional Market Analysis 1. Comparison with Other Chinese ProvincesWhen comparing Gansu to other provinces in China, such as Xinjiang and Sichuan, it becomes evident that Gansu has unique characteristics. While Xinjiang is known for its vast oil reserves, Gansu's economy is more diversified, with significant contributions from agriculture, mining, and renewable energy. This diversity presents both challenges and opportunities for the telescopic casing market. 2. Specific Characteristics of the Gansu MarketGansu's market for telescopic casing is influenced by its geographical features and resource availability. The province's mountainous terrain and rich mineral deposits create a demand for specialized casing solutions that can withstand challenging conditions. Additionally, Gansu's strategic location as a transportation hub enhances its potential as a market for telescopic casing. III. Factors Influencing the Market Size in Gansu A. Economic Factors 1. GDP Growth RateGansu's GDP growth rate has shown promising trends in recent years, reflecting the province's economic resilience. As the economy expands, the demand for industrial products, including telescopic casing, is expected to rise. A growing GDP often correlates with increased investments in infrastructure and energy projects, further driving market demand. 2. Industrial DevelopmentThe industrial development in Gansu is characterized by a focus on sustainable practices and technological advancements. The province is investing in modernizing its manufacturing capabilities, which is likely to enhance the production of telescopic casing and related products. B. Demand from Key Industries 1. Oil and GasThe oil and gas industry remains a primary driver of demand for telescopic casing in Gansu. With ongoing exploration and production activities, the need for reliable casing solutions is paramount. The province's efforts to attract investment in this sector will likely bolster market growth. 2. ConstructionThe construction industry in Gansu is also a significant contributor to the demand for telescopic casing. As urbanization accelerates and infrastructure projects are initiated, the need for durable and adaptable casing solutions will increase. 3. MiningGansu is rich in mineral resources, making mining another key industry influencing the telescopic casing market. The extraction of minerals requires specialized casing solutions to ensure safety and efficiency, further driving demand. C. Supply Chain Dynamics 1. Local ManufacturersLocal manufacturers in Gansu are beginning to emerge, providing telescopic casing solutions tailored to the specific needs of the region. This local production can enhance supply chain efficiency and reduce costs, making it an attractive option for businesses in the area. 2. Import and Export TrendsGansu's strategic location facilitates trade, allowing for both imports and exports of telescopic casing. Understanding these trends is crucial for estimating market size, as they can significantly impact pricing and availability. IV. Market Size Estimation A. Methodology for Estimating Market Size 1. Data SourcesTo estimate the market size of telescopic casing in Gansu, various data sources are utilized, including industry reports, government publications, and market surveys. These sources provide valuable insights into current market conditions and future projections. 2. Analytical TechniquesAnalytical techniques such as market modeling and trend analysis are employed to derive accurate estimates. By examining historical data and current market dynamics, a clearer picture of the market size can be formed. B. Current Market Size of Telescopic Casing in GansuAs of the latest estimates, the market size of telescopic casing in Gansu is projected to be substantial, reflecting the province's industrial growth and demand from key sectors. While exact figures may vary, the overall trend indicates a positive outlook for the market. C. Forecasting Future Growth 1. Short-term ProjectionsIn the short term, the market for telescopic casing in Gansu is expected to grow steadily, driven by ongoing investments in infrastructure and energy projects. The demand from the oil and gas sector, coupled with construction activities, will contribute to this growth. 2. Long-term ProjectionsLong-term projections suggest that the market will continue to expand, with technological advancements and increased industrialization playing a significant role. As Gansu positions itself as a key player in various industries, the demand for telescopic casing is likely to rise. V. Challenges and Opportunities A. Challenges Facing the Telescopic Casing Market in Gansu 1. Regulatory IssuesOne of the challenges facing the telescopic casing market in Gansu is navigating regulatory frameworks. Compliance with safety and environmental regulations can pose hurdles for manufacturers and suppliers. 2. Competition from Other RegionsGansu faces competition from other provinces with established oil and gas industries, such as Xinjiang and Sichuan. This competition can impact market share and pricing strategies for telescopic casing. B. Opportunities for Growth 1. Technological AdvancementsTechnological advancements present significant opportunities for growth in the telescopic casing market. Innovations in materials and manufacturing processes can enhance product performance and open new applications. 2. Emerging MarketsAs Gansu continues to develop its industrial base, emerging markets within the province can provide new avenues for growth. Targeting sectors such as renewable energy and sustainable construction can further expand the market for telescopic casing. VI. Conclusion A. Summary of Key FindingsThe market size of telescopic casing quotations in Gansu is influenced by various factors, including economic growth, demand from key industries, and supply chain dynamics. The province's unique characteristics and ongoing industrial development position it as a promising market for telescopic casing solutions. B. Implications for StakeholdersFor stakeholders, understanding the market dynamics and potential growth opportunities is crucial for making informed decisions. Manufacturers, suppliers, and investors should consider the evolving landscape and adapt their strategies accordingly. C. Future Outlook for the Telescopic Casing Market in GansuThe future outlook for the telescopic casing market in Gansu is positive, with expected growth driven by industrialization, technological advancements, and increasing demand from key sectors. As Gansu continues to develop, the market for telescopic casing is likely to thrive, presenting opportunities for innovation and investment. VII. References A. Academic Journals- Journal of Petroleum Science and Engineering- International Journal of Mining Science and Technology B. Industry Reports- Global Telescopic Casing Market Report- Gansu Economic Development Report C. Government Publications- Gansu Provincial Bureau of Statistics- Ministry of Natural Resources of the People's Republic of China---This blog post provides a comprehensive overview of the market size of telescopic casing quotations in Gansu, highlighting key trends, influencing factors, and future projections. By understanding the dynamics of this market, stakeholders can better navigate the opportunities and challenges that lie ahead.